Rangvishwa brings transformational technology with finest and reliable printed electronics for its customers. Rangvishwa offers an array of a variety of conductive inks for printed electronics to adapt to the multitude of different applications like sensors, touch screens, touch switches, printed heaters and more. For a better understanding of this revolutionizing technology, it’s working, its application, its scope and development lets dive deeper into this blog.

What are Printed Electronics?

Printed Electronics are used in various applications with the advancing technology. Flexible screens, interactive books and posters, intelligent labels and packaging are made with Printed Electronics.

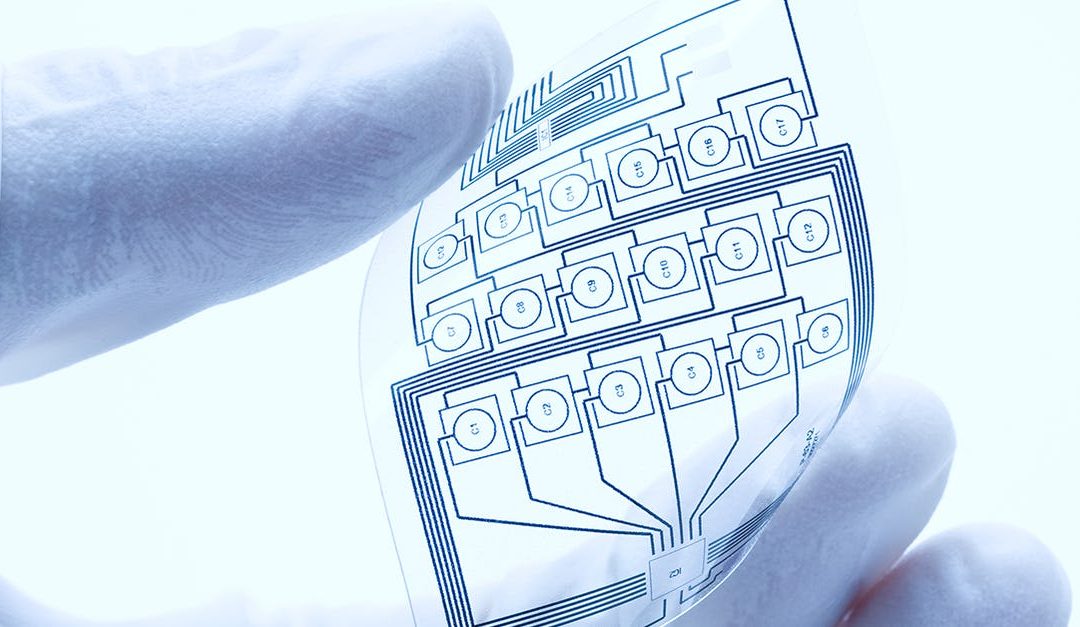

Printed Electronics can be stated as a set of printing methods used to produce numerous electronic devices on various substrates. Typically, electronic industries use printing equipment suitable for exemplifying patterns on different materials, like screen printing, flexography, offset lithography and inkjet. Electrically optical links are deposited on the substrates, making passive or active devices. This technology matured and unfolded its true potential over years, now inkjet printer is making inexpensive and quick printed electronic circuits.

Printed Electronics and its development

With the advancement of technology, Printed Electronics is gaining momentum. An increasing number of manufacturing industries are using Printed Electronics. Flexible screens, interactive books and posters, intelligent labels and packaging, and upholstery are being created with the use of printed technology. To fit the growing technology production lines, Printed Electronics has evolved to be thinner, lighter and more flexible. From sensors for autonomous driving or light-emitting diodes in the world of smart clothing, many such sectors depend on the lightweight and flexible electronic components. Wolfgang Mildner, CEO of the consulting and technology company MSW said, “Printed electronics has evolved into a cross-sectional and key technology.” The main focus of limelight falls on human-machine interactions and 3D-structured electronics and innovative material of this industry.

Printed Electronics has a foothold in the medical industry for many years which still is flourishing and further advancing. Sensors that help monitor various functions of bodies and micro-fluids (lab-on-a-chip) for quick test placed at the bedside used in medical diagnostics contribute to this industry. A consulting firm Mordor Intelligence assumes that printed electronics market will be widespread by almost 2023.

Aerospace yet another promising industry for Printed Electronics is still being explored. Dannis Hahn from Airbus describes the website ‘Inside Composites’ that he has carried interest in Printed Electronics for more than 20 years now. However, at that time the materials didn’t meet the safety standards for aviation used in this technology. But he saw potential which does show extreme value today, ‘a lot has changed since then’ said Dennis. Contributing to many other industries like automobiles, household machinery and more the market for this revolutionary technology is ever-growing.

Rangvishwa’s development in Printed Electronics

One of the leading manufacturers of Printed Electronics, Rangvishwa Enterprises offer several flexible printed electronics to its wide range of customer base. Providing superior quality and an array for many industries Rangvishwa has successfully launched a new member to the product line, ‘Flexible Printed Heater’. In simple words ‘Flexible Printed heaters’ are warming elements. They act as a warmth provider to appliances, clothing, products, etc. A flexible heater is a chemically etched or screen printed heater which can be flexed or bent to conform to the contours of the surface which requires heating. Polyimide/Kapton Film heaters, carbon printed heaters, and transparent heaters are some of the types. These contain the same properties on the general line as that of flexible printed electronics. Vividly growing in the garment industry due to the elasticity and flexibility of the material. Used in retail clothing and sports garments such as athlete gear, also to medical bandages, medical heating pads and more. The flexibility in the construction of Flexible Printed heaters with the advanced materials today can conform to the human body curves while giving the room for mobility, not restricting the movements in any way. As these are light-weighted, it has negligible weight to add to the garments. These properties and functionality make it ideal for its application in the garment and medical industries.

Other lines of products Rangvishwa renders are:

- Flexible Circuits

Flexible Circuits are light-weight, thin electrical circuits that can easily contour to small spaces and curvy contoured shapes. Consisting of conductive material of metal encompassed with insulating dielectric material made usually of polyimide.

- Biosensors

It is an analytical device which helps convert a biological response into an electrical signal. It is made up of transducer and biological element. Mainly used in combination of two fields’ viz. microelectronics and biotechnology.

- Printed Antennas

Also generally termed as planar antennas, these are realized with printed electronics technology. Being a part of electronic miniaturization, this product is spreading like wildfire in the technological industry. Many variants come in different geometric sizes for use in microwaves, radar transponders etc.

- In-mould Electronics

These electronics eliminate the added weight and post-processing activities by authorizing the parts to be directly included in the electronic circuitry in the process of the moulding cycle. This decorating technology works with printed electronics. Benefitting in the enhancement of manufacturing productivity, overall system cost lessens and optimizes design flexibility.

- Electroluminescent Technology

An electroluminescent film is a tool where a layer of the light-emitting phosphor is generally printed between two hugely thin electrodes, one is opaque and the other is transparent. Application of alternating current, the phosphor compound rapidly charges and discharges, resulting in the emission of light that could vary among blue, green, orange or white. Numerous other colours can be attained by adding dyes and filters to the active EL area. The electroluminescent film offers an array of advantages over other lighting sources: energy efficient, low thickness, generating no heat, providing uniform lighting with absolutely no dark areas and versatility.

- Force Sensor

Sir Franklin Eventoff discovered some materials that can change their values of resistance when subjected to force in the 1970s. These materials are called as Force-Sensing Resistors. These materials are typically used to produce a sensor that can measure the Force in a quant-able unit. These respond to applied force and convert the value into a précised measurable quantity. Used in various industries like medical, automotive, music and clothing.

Challenges faced by Printed Electronics Technology

Revolutionary tech it maybe, but with the evolving nature and expanding market Printed Electronics too, are facing challenges. Printing Technology uses printing additional layers increasing the conductivity but this leads to increased material usage and thus heightening the processing time. In the inkjet printing, the current process in use is good but not that efficient which surely is improving with the help of researchers and innovators. The industry is so new that the processes involved in the product line will keep evolving through the critical nature of the trial and error testing. This field has yet to achieve its full potential, as this is just the beginning for Printed Electronics.

Printed Electronics is a futuristic tech with a growing market. This technology with its flexibility and micro nature is contributing to the transformation of all the products it is applied to, bringing a revolution in the technology ecosystem and laying down the foundation for a technological friendly world.

Recent Comments